High Performance Resin Products

NALUX is expanding the application of plastic optical elements by molding resin having special characteristics such as infrared transmissive and high heat resistance, not found in general resin optical materials. NALUX also develops resin materials in collaboration with material manufactures.

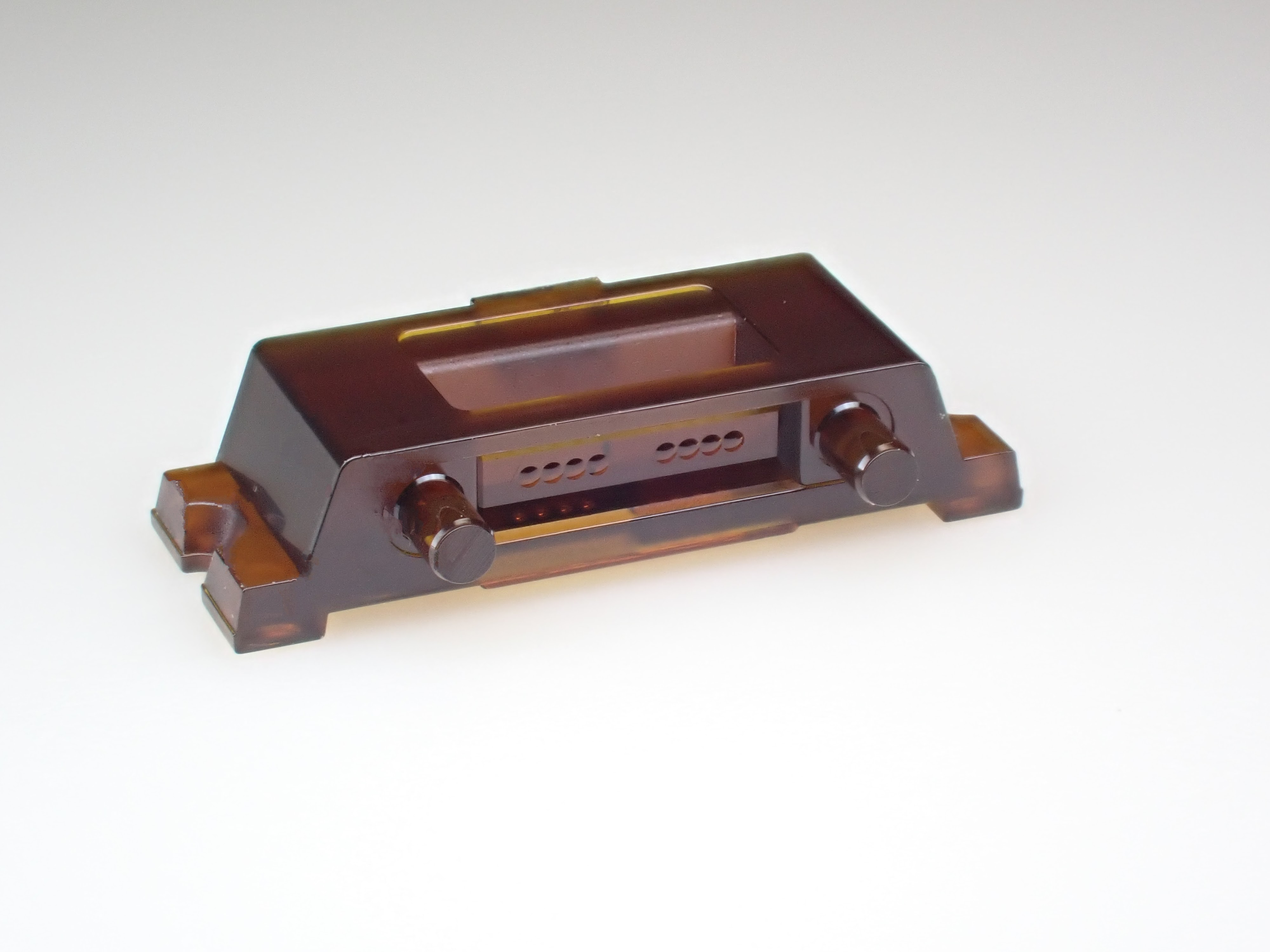

High thermal resistance and high strength resin lenses (EXTEM, ULTEM)

ULTEM and EXTEM resins, made by SABIC, a material manufacturer based in Saudi Arabia, are Polyetherimide (PEI) offering high thermal resistance, strength and stiffness and broad chemical resistance. Offering near-infrared transparency, ULTEM has been selected for many plastic lenses to be used particularly in optical communication where high reliability is essential. EXTEM has enhanced thermal performance and EXTEM lenses are well-stable for the solder reflow process at around 270℃ despite being resin lenses.

Nalux has acquired and accumulated a large amount of knowhow about these resins and molding them, and succeeded in commercializing polymer lenses well-suited to the solder reflow process.

Combining these resins with long-developed technologies in producing optical elements, Nalux is confident of offering ultra-high precision molded components in the applications that require high thermal resistance and broad chemical resistance.

We look forward to your contact for the EXTEM and ULTEM as well as other super engineering plastic molded products.

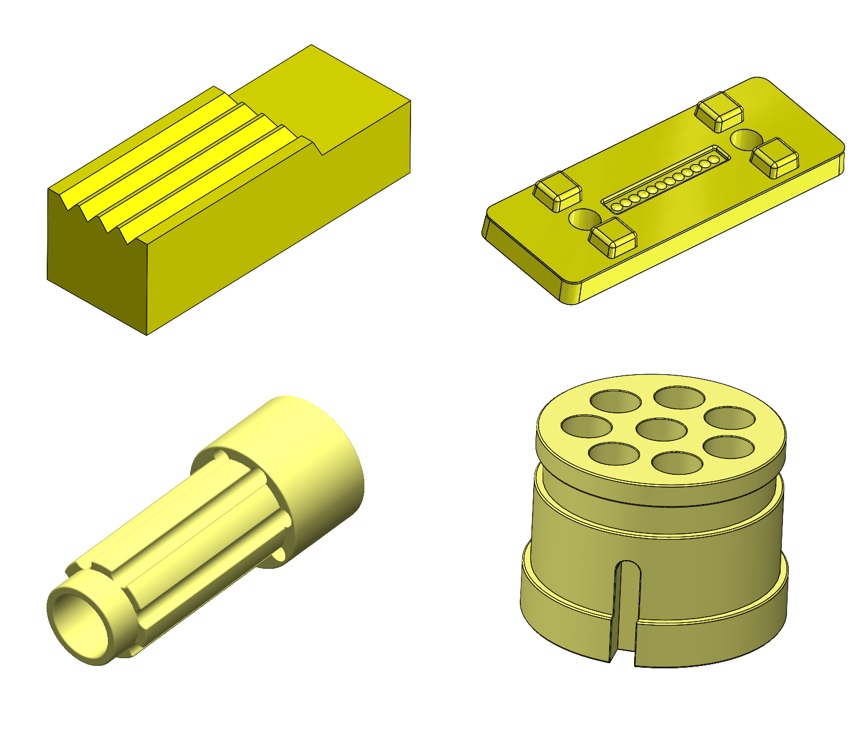

Key Features of Nalux High Thermal Resistance and Strength Components

- Ultra-high heat resistance, capable to withstand the high temperatures of reflow soldering

- High mechanical strength

- High chemical resistance particularly against gasoline, alcohol, weak acid, and weak alkaline

- Able to customize resins best-suited for your purpose

Application Examples

- Plastic optical element well-stable for the solder reflow process

- Weight-saving by replacing metal parts

- Components requiring thermal resistance and chemical resistance

- Applications that require reliability such as medical, automotive and aerospace fields.

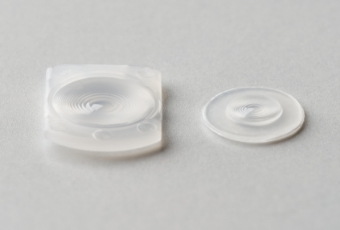

Infrared transparent plastic lens (HDPE lens)

Optical lenses for the infrared range are made of germanium (Ge), chalcogenide glass, or silicon, which are special materials different from those used in the visible light range. However, these are expensive because of the high cost of the materials themselves and the difficulty of processing. In addition, some materials contain toxic substances and require careful handling. To solve these problems, NALUX has been proposing resin optical elements made of high-density polyethylene, a non-toxic resin material, for the far-infrared field.

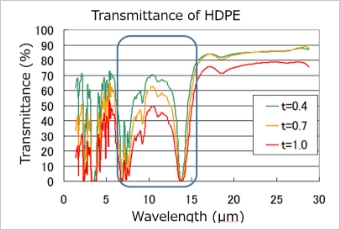

HDPE is a resin material with light transmittance in the infrared range. However, its internal transmittance is low, and sufficient light transmittance cannot be obtained with ordinary lens shapes. NALUX has realized an infrared lens with sufficient transmittance despite being made of resin by reducing the thickness of the lens to the utmost limit using Fresnel lens shape, made with micro fine processing and injection molding technologies. (JP5584870)

This lens is ideal for relatively low-resolution applications, such as spatial temperature sensors, and for systems with strict cost requirements. It can be used not only as a lens, but also as an optical cover or window.

For applications requiring higher resolution, we propose a reflective optical system using plastic free-form mirrors.

Characteristics

- Low cost because of injection mold production process suitable for volume production

- HDPE materials offer good availability and stable supply

- Compact and light weight

- Chemically stable and high chemical resistance

Image video examples